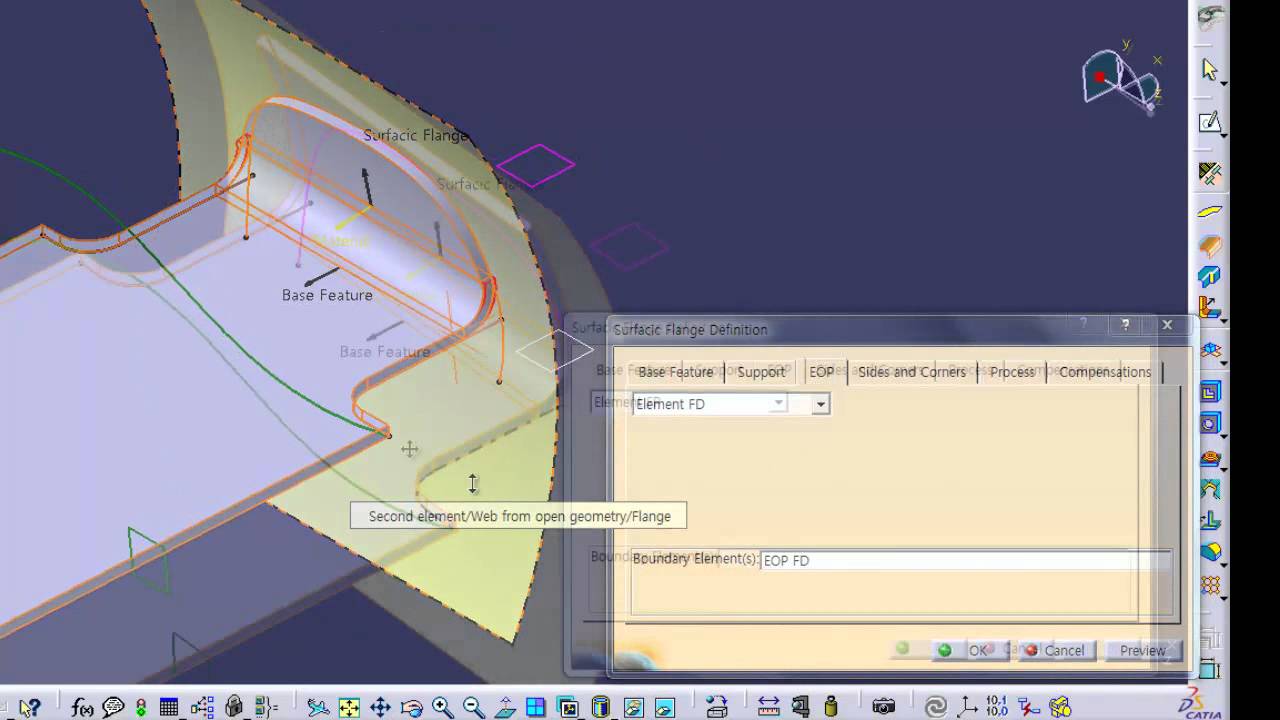

Catia v5 aerospace sheet metal design asl overview catia generative aerospace sheet metal design is a product dedicated to the definition of sheet metal parts used in the aerospace industry hydro pressed or break formed.

Aerospace sheet metal design catia v5.

Company standards and skills can be used to specify features through catia v5 knowledge abilities.

Sheet metal depends on certain parameters 1 thickness 2 bend radius 3 bend angle.

Catia generative aerospace sheetmetal design provides an interactive function to design sheetmetal parts in a very intuitive way taking manufacturing constraints into accounts.

Catia v5 pdf this is widely used when we speak of designing structures related to aerospace as the design engineer needs to take into account the surface material and sheet metal.

L ᴫ 2 r y t θ 90.

It provides the flatpattern of the sheetmetal part and allows easy incremental design from preliminary to detailled stages and modification both in 3d and flattened conditions.

The forte of the.

Encapsulates feature based modeling and makes it available through a handy user interface dedicated to sheetmetal for aerospace.

Catia v5 aerospace sheet metal design asl overview catia generative aerospace sheet metal design is a product dedicated to the definition of sheet metal parts used in the aerospace industry hydro pressed or break formed.

Product key customer benefits.

Aerospace sheet metal design catia v5.

This page uses frames but your browser doesn t support them.

This page uses frames but your browser doesn t support them.

There are four sheet metal design workbenches available in catia v5.

1 introduction sheet metal introduction 2 primary walls and secondary walls 3 sheetmetal parameters 4 k factor and y factor 5 various sheet metal tools 6 creating sheet metal components.

Sheet metal design is primarily used to modify sheet metal parts created in catia v5r14 or earlier and sheet metal production is used to perform validation checks.