Press working operations are also known as sheet metal operations the operations performed on the sheets to get the required shape is called sheet metal operations.

Advantages of sheet metal operations.

Its relatively low cost is also an advantage in both one off design situations and in situations involving large quantities for mass production.

Established in 1903 sheet metal workers local 105 resulting from the merger of local 108 and local 102 serves the southern california counties of los angeles orange riverside san bernardino kern inyo and mono.

By applying surface treatment and finishing to the finished parts they can be resistant to corrosion sun and moisture and are ideal to be used in products that will be exposed to various weathers and climates.

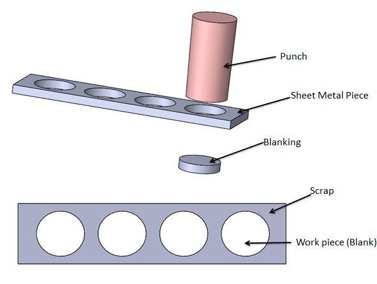

It is an operation of cutting a whole piece from sheet metal.

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more.

Our members are part of the building and construction trades.

Applications and uses 7.

Roll forming this process is for long parts with constant complex cross sections.

Sheet metals are capable of withstanding any sort of pressure without collapsing.

In the last article we had discussed types of dies and types of fits which are performed on sheet metal to get the required shape.

Technological advancements in the equipment used for cutting and forming sheet metal have also led to greater use of the material in a vast number of different applications.

In which enough scrap is left all around as shown in fig.

Many small companies are required to manufacture curved products and shallow parts with fine details in a small lot size which leads to both a higher production cost per detail and a need for multiple tools.

First go through it so that you can understand the current topic must effectively.

This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.

These products have good strength with light weighted characteristic versatility in shapes low cost fast production rate and many more advantages which make is suitable for every manufacturing industries.

A punch and die is applied for this type of sheet metal operation.

Sheet metal enclosure manufacturing involves many different sheet metal forming processes such as roll forming stamping peen forming and more.

22 different types of lathe machine operations.

Spinning is a sheet metal forming process in which a metal blank is pressed over a rotating chuck or form mandrel with the help pressing tool to obtain axisymmetric hollow shell.

Sheet metal operation gives many advantages over forging or casting process which makes it a most versatile operation.

This list compares the good and bad of each process so you can determine the proper one for your own unique requirement.